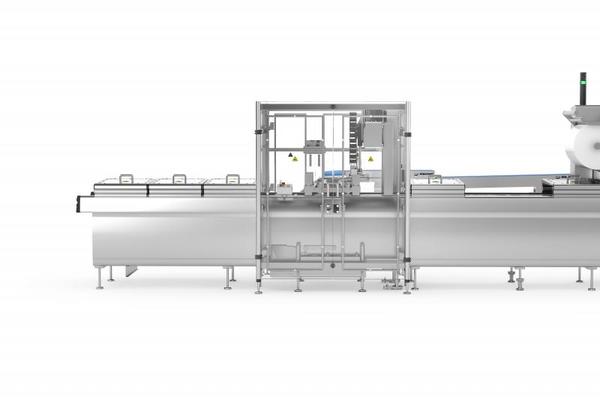

With the H 052 robot from MULTIVAC, a 2-axis robot can for the first time be completely integrated into a thermoforming packaging machine.

This means that the space requirement can be reduced significantly. The handling module can be matched flexibly to a wide range of products and finished packs with a weight of up to four kilos. It automates economically the loading, removing and converging of packs in thermoforming packaging lines.

A standard cycle output of 25 cycles and a standard operating range of 200 by 800 mm - which can be extended as an option if required - make the H 052 a versatile automation module within the packaging line.

The propulsion unit, which is equipped with dynamic linear motors, brings products of up to four kilos in weight to the required position quickly, evenly and accurately. The propulsion unit is equipped with a gripper which, depending on the particular product, weight and pack format, can have a multi-channel design if required. As an option, the module can also be equipped with a fixed pivoting or turning range.

Two variants of the H 052 are available for loading pack cavities with product: either in the running direction of the thermoforming packaging machine or at right angles to it.

If the thermoforming packaging machine is equipped with a complete cutter, the H 052 can be used for converging the packs from the cutting tool. The gripper locates the packs during the cutting process, removes them directly and completely from the cutting tool and then places the packs on a discharge conveyor.

If the H 052 is used to converge packs after the cutting process, it follows the "Good Philosophy" principle and removes only the good packs from the discharge conveyor before feeding them to downstream process stages. Defined ejection of reject packs is controlled by the MLC (MULTIVAC Line Control). Integrating the H 052 in the line control ensures that all quality-related parameters from upstream processes, such as for example product presence or legibility of codes, are transferred to the module.

The conveyors for discharging the packs can be positioned in either the running direction of the packaging machine or at 90 to it.

The operation, recipe management and control of the H 052 are performed at the ergonomic HMI of the thermoforming packaging machine, so that convenience and process reliability are assured.

The necessary safety protection against people reaching into the H 052 is provided by an enclosure made of either transparent polycarbonate or perforated stainless steel plate.